109S系列

|

型 號 Model |

單 位 Unit |

BL109S-3T |

BL109S-5T |

BL10 9S-10 T |

|

|

公 稱 壓 力 Nominal force Out put |

KN |

30 |

50 |

100 |

|

|

液體最大工作壓力 Maximum hydraulic working pressure |

MPa |

14 |

14 |

14 |

|

|

回 程 力 Back storke force |

KN |

30 |

50 |

100 |

|

|

机架台面距地面高度 Height of tale above floor |

mm |

800 |

800 |

800 |

|

|

最 大 開 口 距 離 Biggest operational height |

mm |

200 |

300 |

300 |

|

|

壓 块 最 大 行 程 Maximum stroke of the ram |

mm |

150 |

200 |

200 |

|

|

工作台有效面積 Dimensions of table |

左 右 Left-right |

mm |

400 |

400 |

400 |

|

前 后 Front-back |

mm |

300 |

300 |

300 |

|

|

滑块壓頭速度 Speed of slide |

下行速度 Speed of Down |

mm/s |

≥100 |

≥100 |

≥100 |

|

工进速度 Working speed |

mm/s |

≥20 |

≥20 |

≥20 |

|

|

主幾輪廓 长 宽 高 Overal dimensions of the machine |

mm |

700*600*1900 |

700*600*1900 |

700*600*1950 |

|

|

總 功 率 Motor Power |

KW |

3 |

4.4 |

7.5 |

|

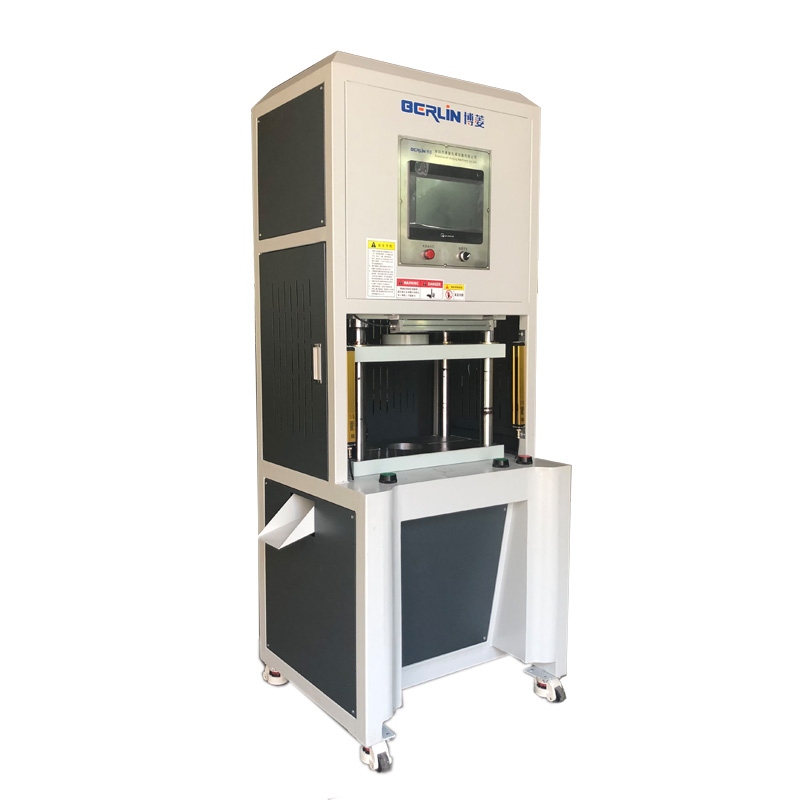

精密数控伺服电子压力机

Precision CNC servo press

简介 Introduction

精密数控伺服电子压力机又称伺服压力机 伺服压装机 电子压力机,工作原理是由伺服电机驱动精密滚珠丝杆进行精密压力装配作业,能够在压力装配作用中实现压装与压入深度的全过程闭环控制,从而实现在线质量管理的过程;结构可根据需求订制分为:四柱型,两柱型弓型等。

Precision CNC servo is also called the servo press machine,servo press machine,electronic press,its working principle is the high precision ball screw driven by servo motor precision pressure assembly operations,can be implemented in the whole process of the closed loop control,so as to realize the online quality control precision of the pressure equipment.The main structure of servo press can be divided into C type arch two columns and four columns.

特点 Features

1 机器具有高精密的压力和位移控制功能,不需要机械限位。加工不同的产品只需调出相应的压装程序,可实现一机多种产品压装

2 所有压装数据可以通过USB接口存在硬盘中,产品加工数据可追溯,方便生产质量管理

3 可设定 一百套不同参数的程序,压装模式有三种可选择,满足不同产品的需求

4 产品的压力 深度 保压时间均可在触摸屏上进行设定,操作简单

5实现精确压力和位移全闭环控制的高精度特性是其它类型压力机所不以比拟的

6 与气动和液压机相比,节能80%以上,且更加环保 安全,可满足无足车间使用要求

7 压力与位移过程曲线可以在触摸屏上显示,生产过程中自动判定产品是否合格,100%实施去不良品,从而实在线质量管理

-

Since the machine itself has precise pressure and displacement control functions,it is necessary to impose a hard limit on the tooling When processing different products,we can only call different pressure loading programs,so we can easily realize the multi-purpose and flexible line.

-

Through the USB interface,the data can be stored in the flash disk,so as to ensure the traceability of product processing data and facilitate the management of production quality control.

-

It can be customized,stored and called 100 sets of pressure assembly.The three kinds of pressure loading modes can be selected to meet your different process requirements.

-

Pressure loading,depth depth pressure protection time,etc.can be input on the operation panel,friendly interface and simple operation.

-

The precise pressure and the high precision of the complete closed-loop control are not comparable with other of press

-

Compares with the traditional pneumatic and hydraulic press,the energy saving effect is over 80%,and more environmentally friendly and safe,which can meet the requirements of the equipment in the dustless workshop

-

Process of force and displacement,being connected graph ca be displayed in the LCD touch screen,the whole process control can be automatically determine whether the product is qualified in any of the stage,100% implementation of removing bad product,so as to operation.